Empowering Business to Evolve, Strategize, Modernize and Excel in Plastic Processing

Launching .....

Remote Consultancy Service

Tailored Solutions for Manufacturing Excellence

Expertise and Knowledge That Drive Impact

Quality and Excellence at the Core of Every Solution

Strategic Remote Consulting

Efficient, Impactful, Cost-Smart, Our remote consulting framework is meticulously engineered to maximize client value and minimize operational waste. By eliminating logistical constraints, we deliver high-level expertise with streamlined efficiency. Clients benefit from rapid access to specialized insights without compromising on quality or engagement. Using advanced virtual collaboration tools, we maintain precision, confidentiality, and agility across all projects. Tailored strategies are delivered securely, enabling informed decision-making from any location. This model promotes lean operations while enhancing responsiveness to dynamic market needs. Experience consulting designed for today’s business reality—agile, economical, and result-oriented. Reallocate resources where they matter most, and elevate performance through smarter engagement.

Key milestones in our Professional Journey

From Machine Builders to being strategic partners to some of the most reputed machine brands, then to Custom Project Building for end customers, our key milestones reflects our commitment to empowering business towards success.

1974-1993

Rated as one of the most reputed Engineering Enterprise supplying spare parts to top Indian Machine Brands & Processing Enterprises

1994-2000

Supplying Upgraded and Customized Machine Cells to End Customers

2001-2009

Collaboration with one of the most reputed International Machine Manufacturer (Manufacturing 5000 + Machnes Annually) on launching and supplying Injection Moulding Machines in the Indian Market

2010-2019

Successfully Operationalizing JV with International Manufacturer to Locally Manufacture and Supply Injection Moulding Machines, Automation Equipment's, Auxiliary Equipment's and Supporting Devices

2020-2024

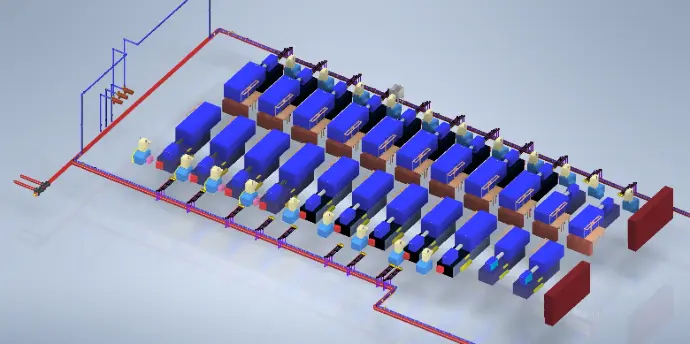

Formal Launch of Specialized Service on Plant / Project Designing, exclusively for Plastic Processing Infrastructure, covering all 3 segments - Extrusion, Blow Moulding and Injection Moulding

2025

Remote Consultation - Revolutionary Vision to reach out to market depths with real time solutions and consultation on transforming Manufacturing Activity to match present and future challenges